10 Key Benefits of Supply Chain Intelligence for Analysts

10 Key Benefits of Supply Chain Intelligence for Analysts

Overview

This article highlights ten key benefits of supply chain intelligence for analysts, focusing on its significant role in enhancing operational efficiency, risk management, collaboration, and adaptability to market changes. Each benefit is presented with practical examples and data, illustrating how access to unique datasets and real-time analytics can lead to improved decision-making, reduced costs, and a competitive edge in logistics management.

What makes supply chain intelligence so crucial? First, it provides analysts with the ability to access and analyze vast amounts of data. This feature allows for better risk management, as organizations can identify potential disruptions before they escalate. The advantage here is clear: by anticipating risks, companies can implement strategies to mitigate them, ultimately saving time and resources.

Moreover, collaboration across departments is enhanced through shared insights derived from real-time analytics. This fosters a culture of teamwork and informed decision-making. The benefit? Teams can respond more swiftly to market changes, ensuring that the organization remains agile and competitive.

In conclusion, the integration of supply chain intelligence not only streamlines operations but also empowers analysts to make data-driven decisions that can significantly impact the bottom line. As you consider these insights, think about how your organization can leverage these datasets to improve efficiency and gain a competitive advantage in the logistics landscape.

Introduction

Supply chain intelligence is rapidly reshaping logistics and operations. It allows analysts to leverage a wealth of unique datasets, enhancing decision-making processes. By utilizing alternative information and real-time analytics, organizations can uncover insights that drive efficiency, reduce costs, and bolster security.

As global supply chains become increasingly complex, businesses face the challenge of effectively leveraging these advancements. How can they navigate these challenges while seizing new opportunities for growth? Understanding the features of supply chain intelligence is crucial. It provides organizations with the ability to analyze diverse datasets, leading to informed decisions that can significantly impact their operations.

The advantages of harnessing this intelligence are clear. Organizations can:

- Streamline processes

- Identify potential risks

- Enhance overall performance

The benefits extend beyond mere efficiency; they also encompass improved security measures and cost reductions.

In this evolving landscape, it’s essential for businesses to consider how they can apply these insights to their operations. What strategies can they implement to fully capitalize on the potential of supply chain intelligence? By exploring these questions, organizations can position themselves for success in a competitive market.

Initial Data Offering: Access Unique Datasets for Enhanced Supply Chain Insights

Initial Data Offering (IDO) serves as a crucial resource for researchers looking to enhance supply chain intelligence through access to a diverse array of datasets. These datasets include alternative information, ESG insights, and fundamental metrics, all designed to help evaluators identify trends, improve operations, and refine decision-making processes. By leveraging these datasets, analysts gain a comprehensive view of performance, allowing them to pinpoint key areas for improvement.

The impact of alternative information on supply chain performance in 2025 is particularly noteworthy. Analysts who utilize alternative information have reported substantial improvements in operational efficiency and strategic planning. For instance, a recent case study highlighted how a major retailer harnessed alternative information to optimize inventory management, resulting in a 15% reduction in stockouts and a 20% increase in customer satisfaction.

Practical examples further illustrate the effectiveness of alternative information in logistics insights. Experts across various industries have successfully integrated alternative datasets to predict demand more accurately and mitigate risks associated with logistical disruptions. One expert noted, "The insights obtained from alternative data have revolutionized our strategy for logistics management, enabling us to foresee market changes and react proactively."

By providing access to high-quality, unique datasets, IDO empowers researchers to fully harness the potential of supply chain intelligence for data-informed decision-making. This ultimately leads to enhanced outcomes across supply networks. How might these datasets transform your approach to logistics management?

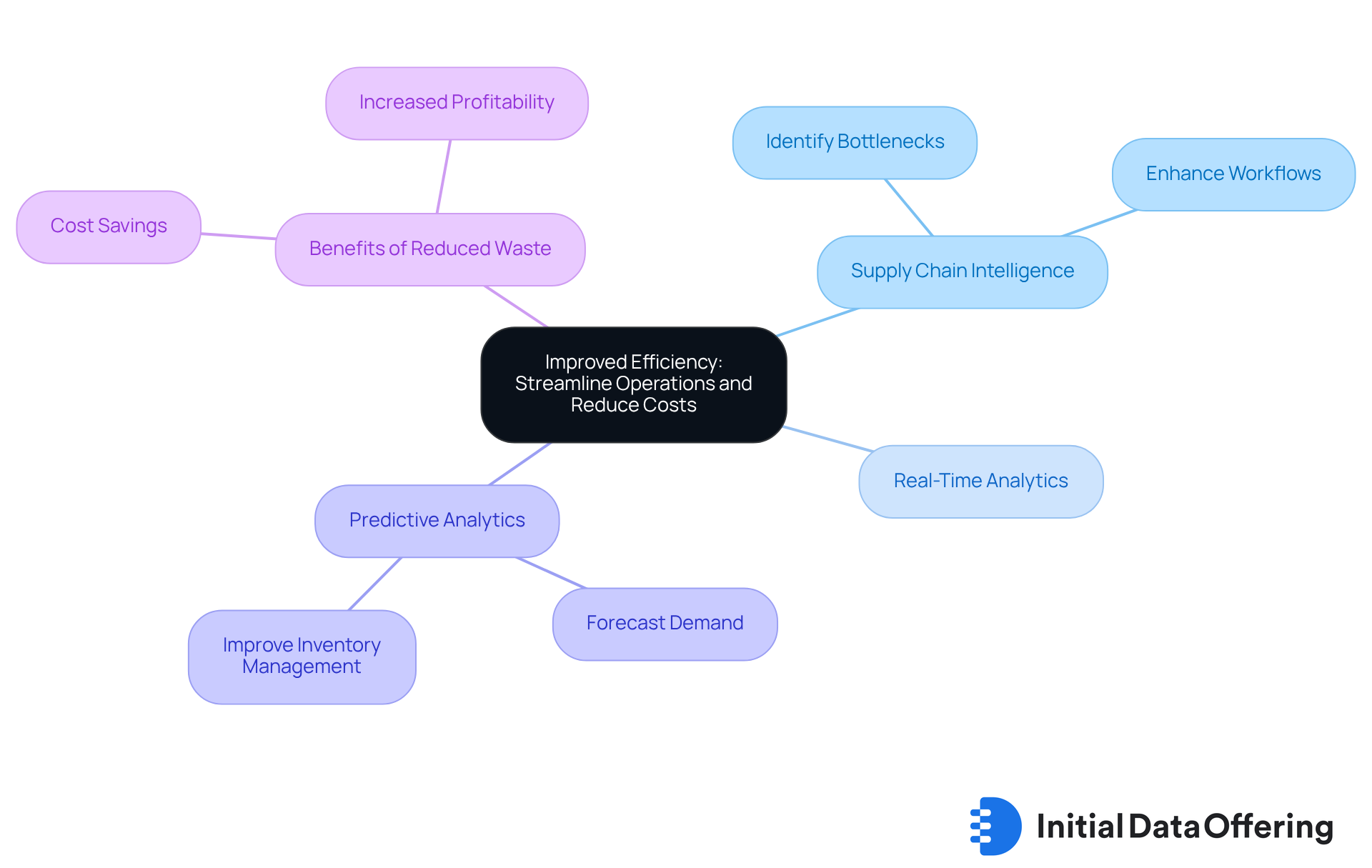

Improved Efficiency: Streamline Operations and Reduce Costs

Supply chain intelligence serves as a crucial tool for analysts aiming to pinpoint bottlenecks and inefficiencies in their operations. What if you could streamline your processes and cut costs significantly? By leveraging real-time information analytics, organizations can not only enhance their operational efficiency but also reduce waste. For example, predictive analytics allows businesses to forecast demand with greater accuracy, leading to improved inventory management and lower holding costs.

The advantages of utilizing supply chain intelligence are clear. Organizations can identify areas for improvement and implement changes that lead to more efficient workflows. This not only saves time but also contributes to a healthier bottom line. Imagine the impact of reduced waste on your overall profitability!

In conclusion, adopting supply network intelligence can transform how organizations operate. By embracing these insights, businesses can make informed decisions that drive efficiency and cost savings. Are you ready to take your operations to the next level?

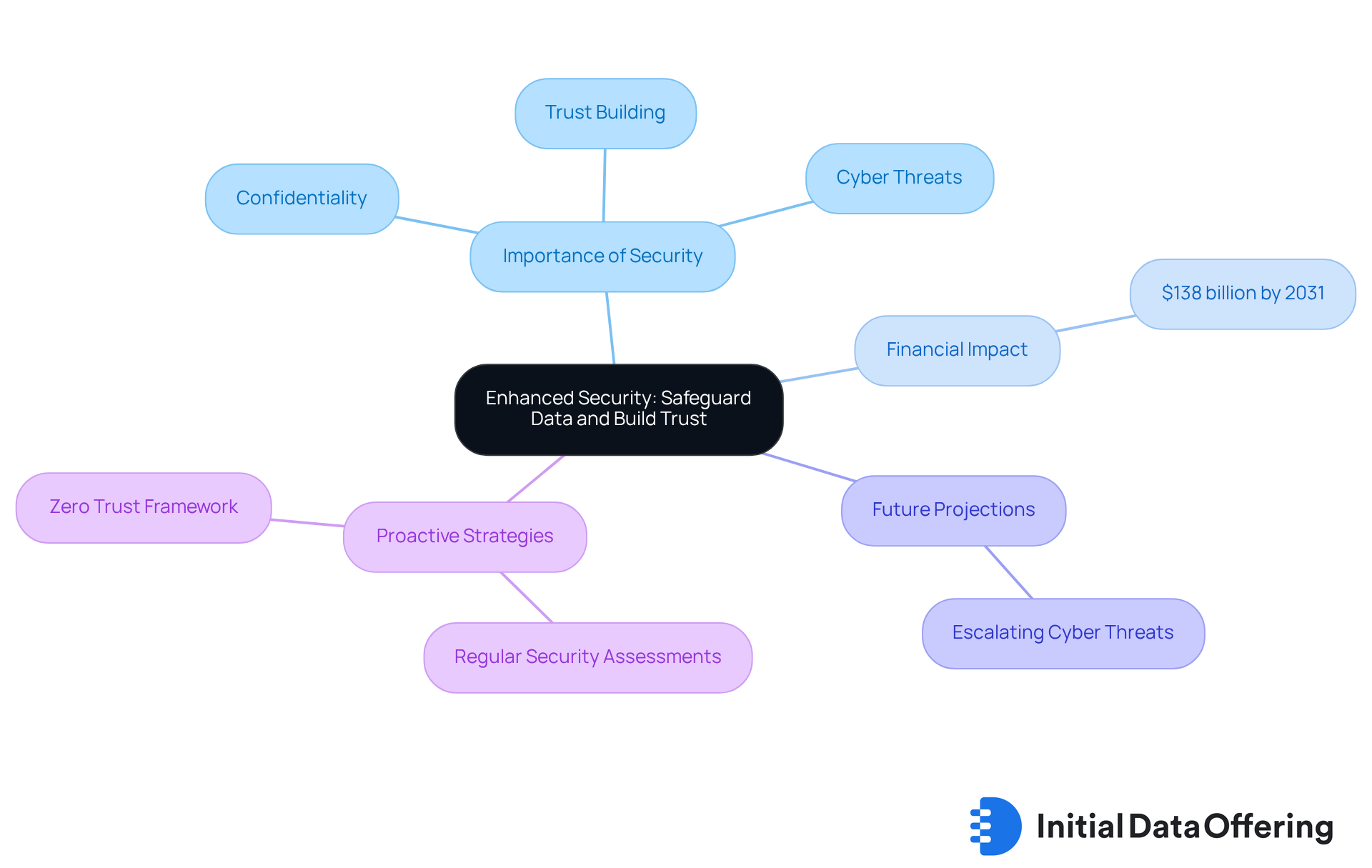

Enhanced Security: Safeguard Data and Build Trust

As organizations increasingly rely on digital information, establishing robust security protocols becomes essential for safeguarding confidential logistics details. Analysts can utilize logistics intelligence tools that incorporate strong security measures, effectively protecting information against breaches. For example, the 2023 SolarWinds attack illustrates how a single vulnerability can compromise numerous organizations, leading to significant financial losses and operational disruptions.

According to industry reports, the global annual cost of software distribution attacks is projected to reach $138 billion by 2031. This statistic underscores the urgent need for rigorous security measures. By prioritizing information protection, companies not only shield themselves from potential threats but also build trust with partners and customers.

Looking ahead to 2025, the emphasis on security measures in logistics information management will be crucial as organizations face escalating cyber threats. Industry leaders advocate for transparency and stringent security protocols, recognizing that trust is cultivated through continuous information protection efforts.

To effectively safeguard logistical information, organizations should adopt a proactive strategy that includes:

- Regular security assessments

- Implementation of a Zero Trust framework

This approach not only enhances security but also fosters a culture of vigilance and resilience against emerging threats.

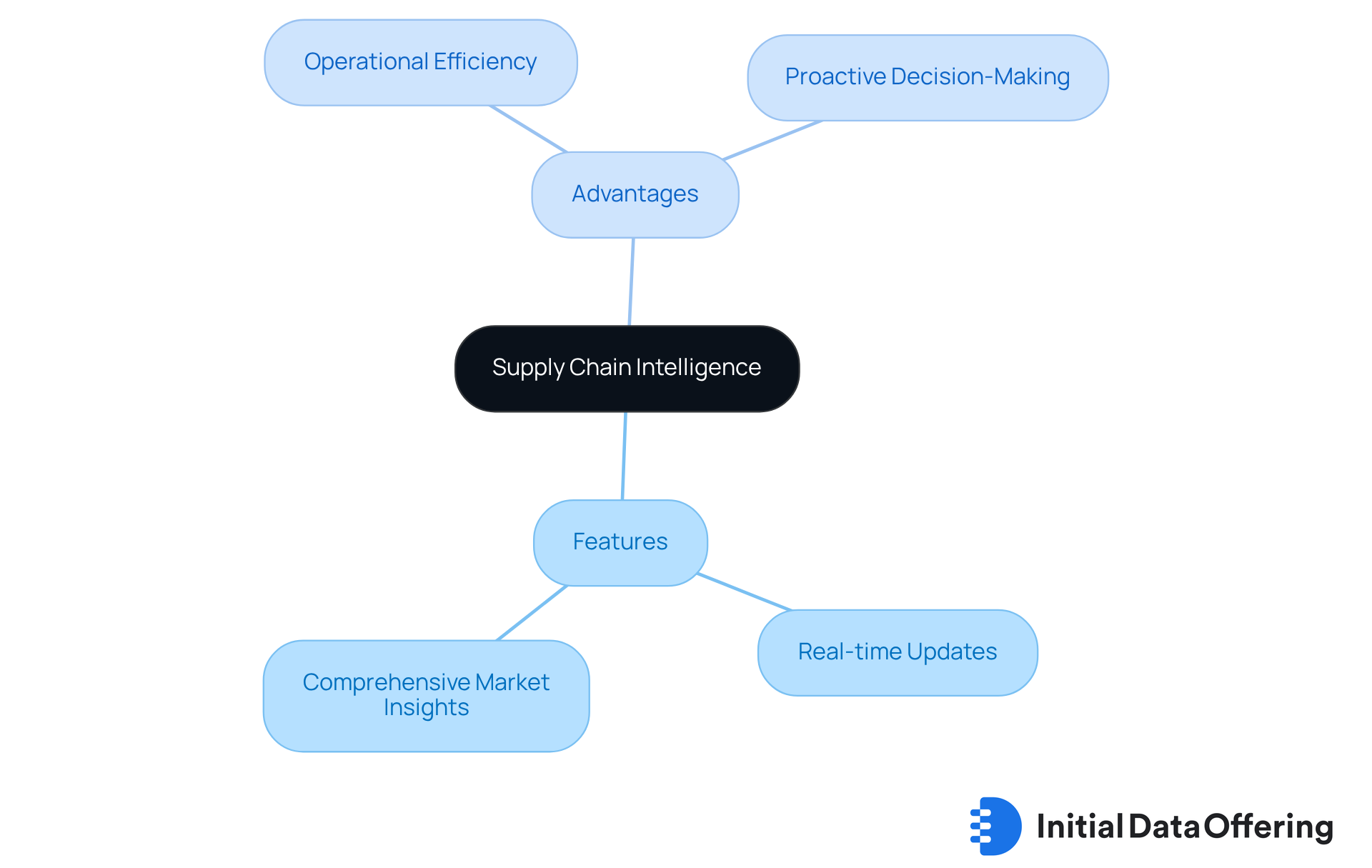

Peace of Mind: Rely on Accurate and Timely Data

Supply network experts can achieve peace of mind by relying on the supply chain intelligence provided by accurate and timely information from platforms like IDO. What if you could make decisions based on the latest market conditions? Access to up-to-date datasets not only ensures that your decisions are informed through supply chain intelligence but also significantly reduces the risk of errors that could lead to costly mistakes. This reliability is essential for maintaining operational continuity and effective strategic planning.

The features of these datasets, which include real-time updates and comprehensive market insights, are crucial for enhancing supply chain intelligence. The advantages are clear: with the right information at your fingertips, you can respond swiftly to changes in the market landscape. Imagine the benefits of making decisions that are not just reactive but proactive. By leveraging these insights into supply chain intelligence, you can enhance your operational efficiency and drive better outcomes for your organization.

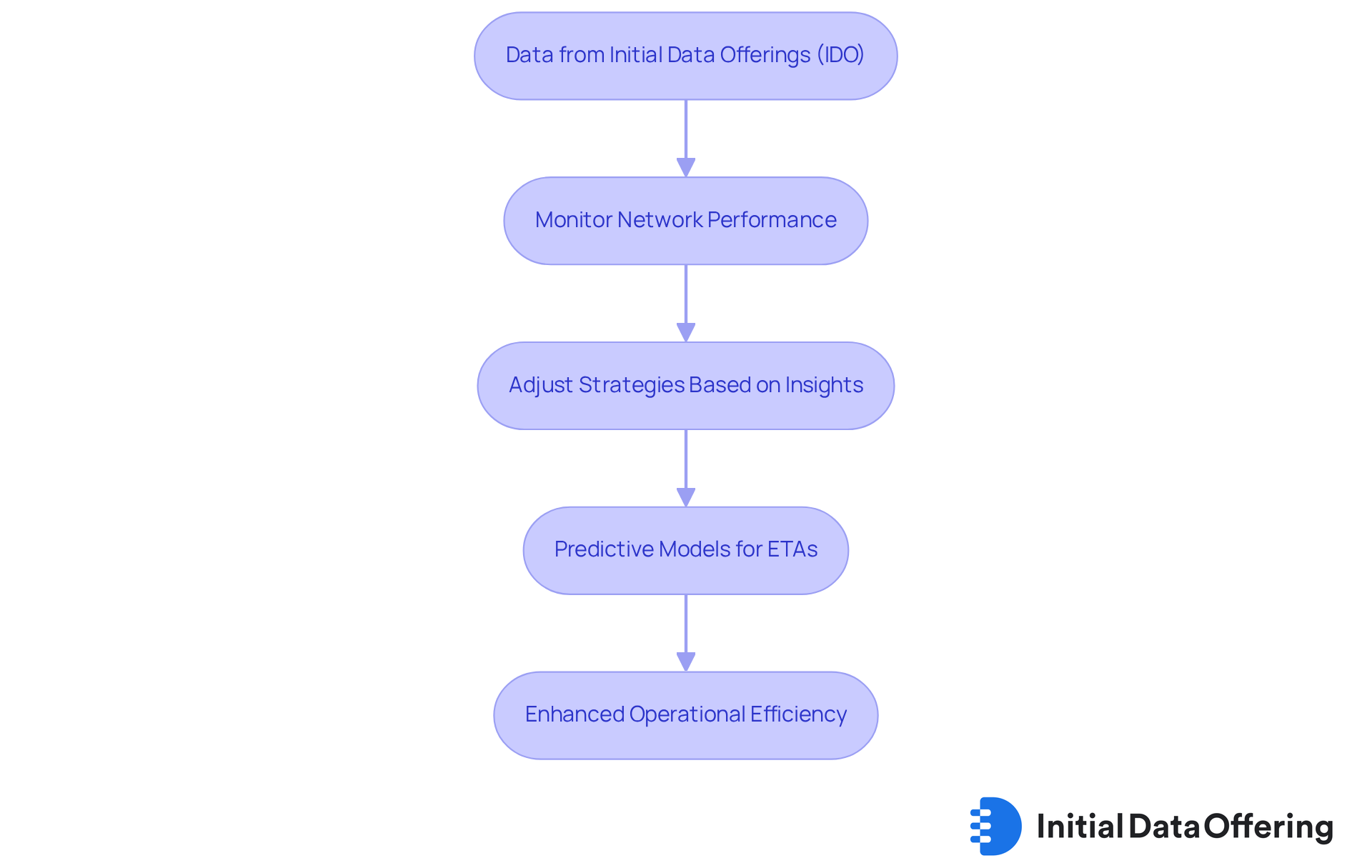

Data-Driven Insights: Make Informed Decisions with Real-Time Analytics

Real-time analytics serve as a powerful tool for logistics evaluators to utilize supply chain intelligence, enabling them to make quick, informed choices. By harnessing data from Initial Data Offerings (IDO), analysts can consistently monitor network performance, allowing for immediate strategy adjustments in response to evolving circumstances. This agility is essential in today’s fast-paced market, where disruptions can occur without warning.

For example, organizations leveraging IDO datasets have reported notable enhancements in their responsiveness to delays. In fact, 30-50% of shipments from Asia to US East Coast ports have faced delays ranging from 14 to 20 days. By utilizing predictive models, such as those discussed in the case study on 'Updated ETAs via Machine Learning,' companies can recalibrate estimated times of arrival (ETAs) based on shifting vessel routes. This not only improves planning and coordination but also enhances overall operational efficiency.

Analysts emphasize that supply chain intelligence derived from data-driven insights empowers proactive decision-making and significantly boosts logistical agility. This allows businesses to effectively manage challenges while maintaining operational efficiency. As Keith DiGiorgio aptly notes, "In the constantly changing environment of logistics, one constant persists as we approach 2024: the frequency of disruptive incidents." How can your organization leverage these insights to navigate the complexities of logistics more effectively?

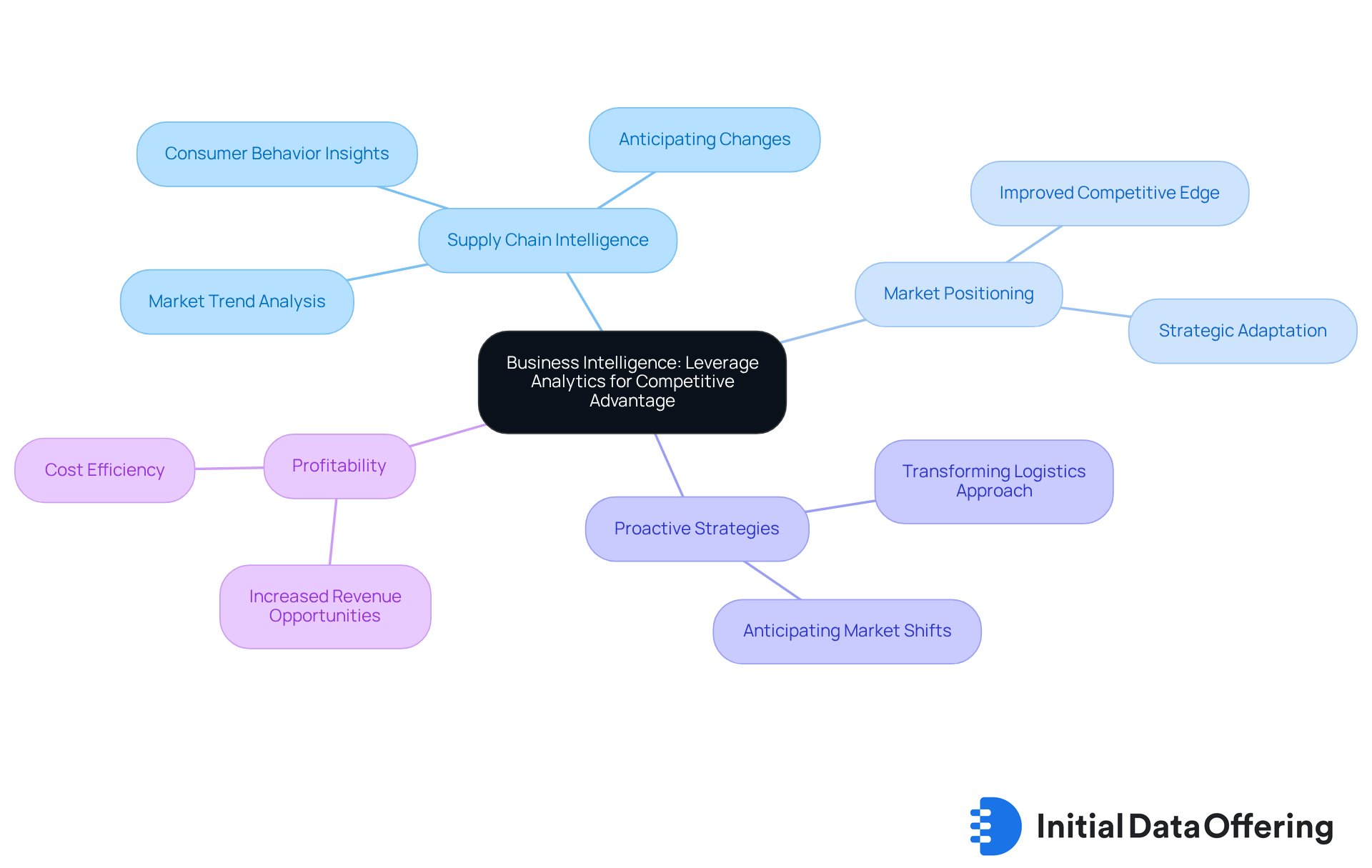

Business Intelligence: Leverage Analytics for Competitive Advantage

By utilizing supply chain intelligence tools, logistics evaluators can gain a significant competitive edge. IDO’s datasets offer a comprehensive analysis of market trends and consumer behavior. This feature allows organizations to anticipate changes effectively.

What does this mean for your organization? By leveraging these insights, you can adapt your strategies proactively. This advantage can lead to improved market positioning and increased profitability.

In today’s fast-paced environment, staying ahead of the curve is crucial. Organizations that harness the power of supply chain intelligence not only respond to market shifts but also shape them. Consider how these datasets can transform your approach to logistics and strategy.

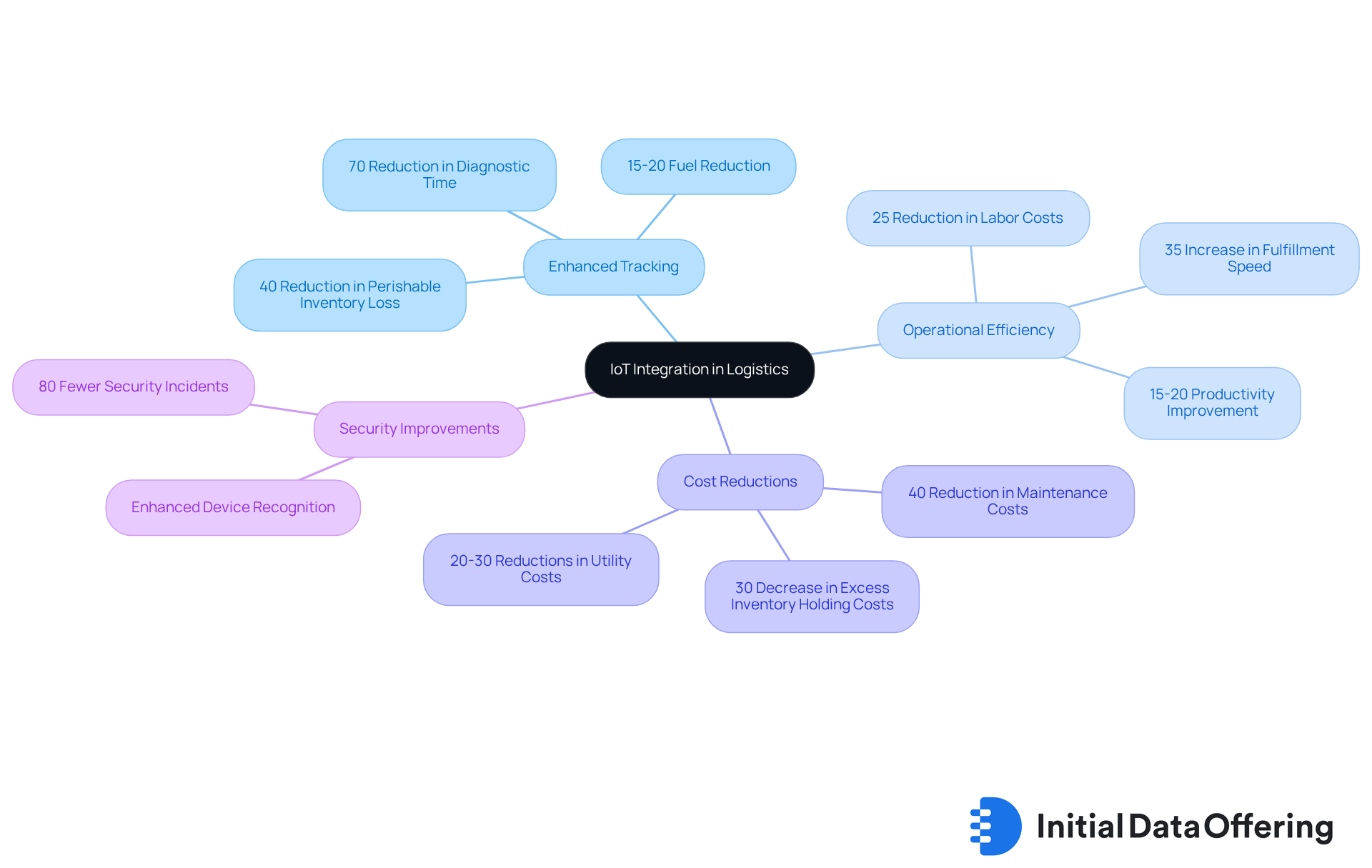

IoT Integration: Enhance Tracking and Operational Efficiency

Incorporating Internet of Things (IoT) technology into logistics operations significantly enhances tracking and operational efficiency. By utilizing information from IoT devices, analysts can monitor inventory levels in real-time, track shipments, and improve logistics processes. This integration not only enhances visibility throughout the logistics network but also enables quicker responses to potential disruptions, ultimately leading to better-informed decision-making driven by supply chain intelligence.

For instance, transportation companies that leverage IoT for optimizing routes and tracking fuel efficiency have achieved fuel consumption reductions of 15-20%. This improvement comes alongside enhanced delivery times and decreased vehicle maintenance needs. Furthermore, logistics companies employing IoT-enabled automation in warehouse operations have seen a 35% increase in fulfillment speed, while labor costs associated with inventory management have dropped by nearly 25%. Similarly, businesses that implement IoT asset tracking systems report a 40% reduction in perishable inventory loss, showcasing the technology's effectiveness in minimizing waste and boosting operational efficiency.

Moreover, organizations adopting comprehensive IoT security frameworks experience up to 80% fewer security incidents, ensuring that their tracking systems remain robust and reliable. As industry leaders emphasize, transitioning to IoT asset tracking has revolutionized processes by providing real-time data, improving accuracy, and enabling proactive decision-making.

Practical examples further illustrate the advantages of IoT in logistics. Companies like Siemens and General Electric have reported productivity improvements of 15-20% within the first year of implementing IoT solutions in their manufacturing facilities. This demonstrates how IoT not only enhances tracking capabilities but also boosts overall operational efficiency, making it a crucial element of supply chain intelligence in modern logistics management.

How can your organization leverage IoT technology to improve logistics operations? Consider the potential benefits and efficiencies that could be gained by adopting these innovative solutions.

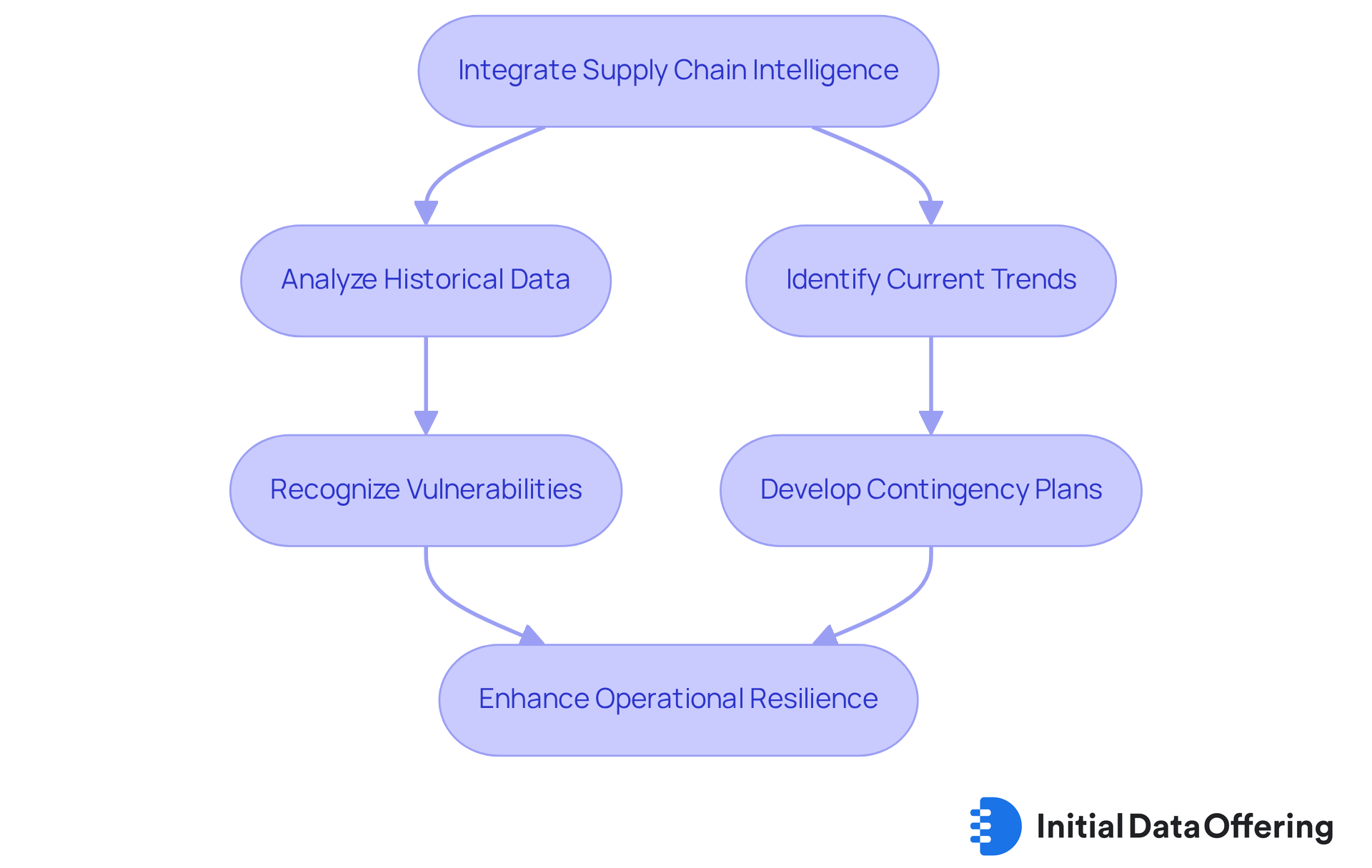

Risk Management: Anticipate and Mitigate Supply Chain Disruptions

Supply chain intelligence is crucial for effective risk management. It empowers analysts to anticipate and mitigate potential disruptions. By analyzing historical data and current trends, organizations can identify vulnerabilities in their logistics. This proactive strategy not only minimizes the impact of unexpected events but also ensures operational continuity.

What if your organization could foresee disruptions before they occur? By leveraging supply chain intelligence, companies can develop robust backup plans tailored to their specific needs. This foresight allows for a smoother response to unforeseen challenges, ultimately safeguarding the organization’s operations.

In summary, the integration of supply chain intelligence into risk management practices offers significant advantages. It enhances the ability to recognize weaknesses, fosters the creation of contingency strategies, and promotes resilience in the face of uncertainty. By adopting this approach, organizations can maintain their operational integrity and thrive even in challenging circumstances.

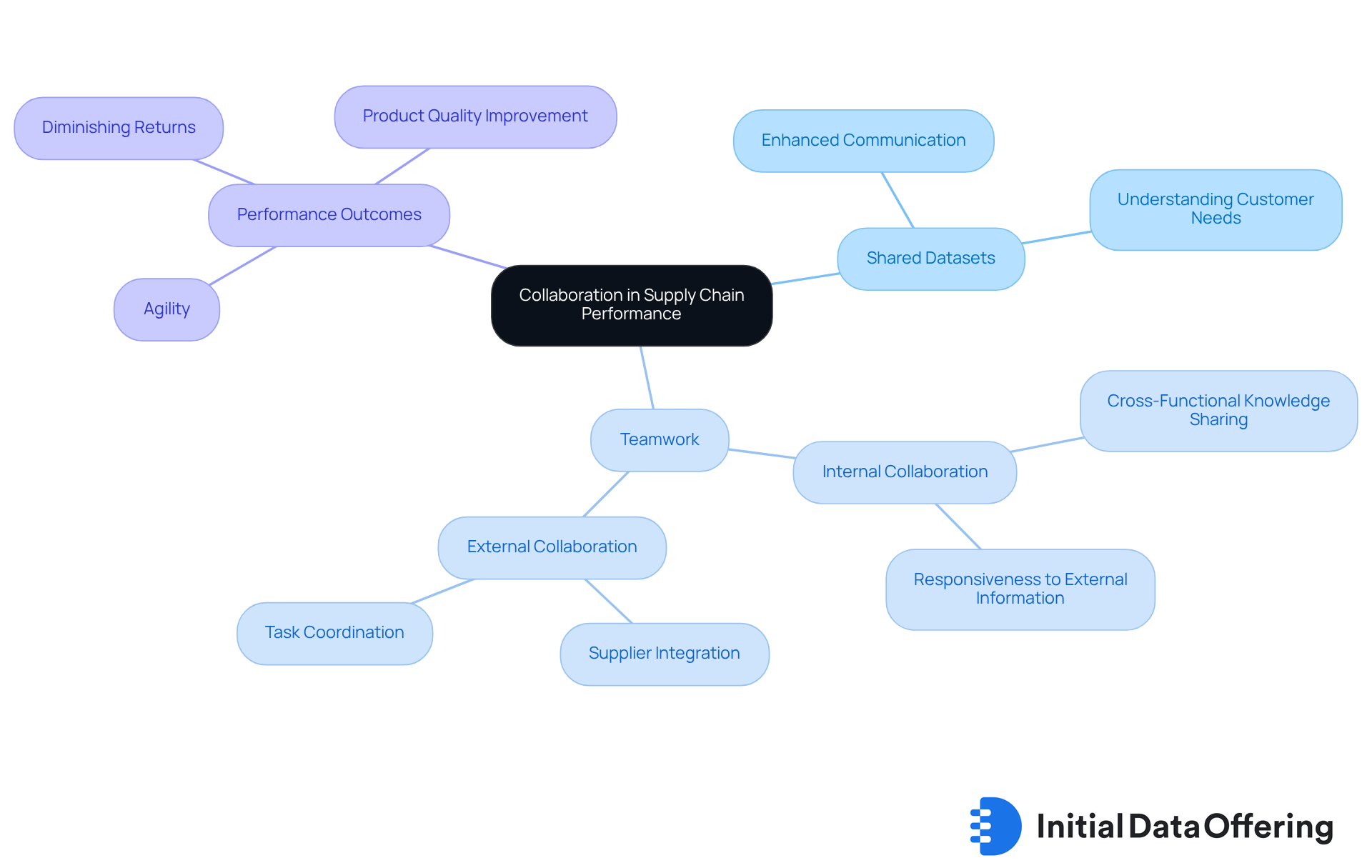

Collaboration: Foster Teamwork for Enhanced Supply Chain Performance

Cooperation between groups is essential for enhancing logistics performance. Shared datasets and analytics tools empower analysts to utilize supply chain intelligence to enhance communication and collaboration across various departments. These features not only promote cohesive strategies but also significantly boost overall efficiency in operational processes.

Empirical research indicates that higher levels of both internal and external collaboration lead to optimal performance. A positive relationship has been identified between teamwork and logistics outcomes. For instance, organizations that effectively utilize shared datasets have reported improvements in task coordination, problem-solving, and product quality by leveraging supply chain intelligence. How can your organization leverage shared datasets to enhance its logistics performance? Analysts have noted that using these datasets allows for a deeper understanding of customer needs, ultimately enhancing value realization.

As one expert pointed out, "internal collaboration is as important as external collaboration," highlighting the critical balance needed for effective teamwork. Furthermore, the concept of the 'arc of integration' illustrates how customer and supplier integration correlates with operational performance, emphasizing the role of supply chain intelligence and shared datasets in achieving this integration. This integration is crucial for fostering a responsive supply network.

However, it is essential to recognize that excessive collaboration beyond a certain threshold can lead to diminishing returns in performance. By emphasizing teamwork through common information, supply networks can attain increased agility and responsiveness, ultimately enhancing performance overall. What steps can you take to ensure your collaboration efforts remain effective?

Future-Ready: Adapt to Changing Market Dynamics with Intelligence

Supply chain analysts must be future-ready to adapt to changing market dynamics. Why is this adaptability crucial? By leveraging supply chain intelligence obtained from data analytics, organizations can stay ahead of trends and shifts in consumer behavior. This proactive approach not only ensures resilience but also positions companies for sustained growth in an ever-evolving marketplace.

Consider the advantages of utilizing data analytics:

- It provides insights that help predict market changes, allowing businesses to respond swiftly.

- The benefits are clear—companies that embrace this adaptability can navigate uncertainties more effectively, ultimately leading to a competitive edge.

In summary, supply chain intelligence enables the ability to analyze and act on data, which is not just a feature of modern supply chains; it’s a necessity for success. How prepared is your organization to leverage these insights for future growth?

Conclusion

Supply chain intelligence serves as a pivotal force for analysts, empowering organizations to leverage data-driven insights that enhance operational efficiency and strategic decision-making. By utilizing unique datasets and real-time analytics, businesses can streamline their operations, mitigate risks, and foster collaboration across departments. This integration of intelligent practices not only boosts performance but also positions companies ahead of market dynamics.

Key arguments emphasize the significance of:

- Accessing diverse datasets

- Employing predictive analytics

- Implementing robust security measures

The advantages of these strategies are clear: they reduce operational costs, enhance data accuracy, and build trust through secure practices. Furthermore, the role of IoT technology in improving tracking and responsiveness highlights the necessity of adapting to evolving market conditions.

Ultimately, embracing supply chain intelligence is not just a competitive edge; it’s a fundamental requirement for sustained growth. Organizations must prioritize these insights to navigate uncertainties and seize opportunities in a rapidly changing landscape. How prepared is your organization to harness the full potential of supply chain intelligence for future success?

Frequently Asked Questions

What is the Initial Data Offering (IDO) and its purpose?

The Initial Data Offering (IDO) provides researchers with access to diverse datasets, including alternative information, ESG insights, and fundamental metrics, aimed at enhancing supply chain intelligence and improving decision-making processes.

How does alternative information impact supply chain performance?

Analysts using alternative information have reported significant improvements in operational efficiency and strategic planning. For example, a major retailer optimized inventory management using alternative data, achieving a 15% reduction in stockouts and a 20% increase in customer satisfaction.

What are some practical applications of alternative information in logistics?

Experts have successfully used alternative datasets to predict demand more accurately and mitigate risks related to logistical disruptions, enhancing their logistics management strategies.

How can supply chain intelligence help organizations?

Supply chain intelligence allows organizations to identify bottlenecks and inefficiencies, streamline operations, and reduce costs through real-time information analytics and predictive analytics for better inventory management.

What are the benefits of adopting supply network intelligence?

By embracing supply network intelligence, organizations can make informed decisions that lead to improved operational efficiency, reduced waste, and ultimately, enhanced profitability.

Why is data security important in logistics management?

As organizations rely more on digital information, robust security protocols are essential to protect confidential logistics details from breaches, which can lead to significant financial losses and operational disruptions.

What are the projected costs associated with software distribution attacks?

The global annual cost of software distribution attacks is projected to reach $138 billion by 2031, highlighting the urgent need for rigorous security measures in logistics information management.

What strategies can organizations implement to safeguard logistical information?

Organizations should adopt a proactive strategy that includes regular security assessments and the implementation of a Zero Trust framework to enhance security and build trust with partners and customers.