10 Ways Manufacturing Data Analytics Boosts Efficiency and Quality

10 Ways Manufacturing Data Analytics Boosts Efficiency and Quality

Overview

Manufacturing data analytics serves as a powerful tool for enhancing efficiency and quality within production environments. By streamlining processes, improving product quality, reducing costs, and optimizing supply chain management, these analytics offer significant advantages. For instance, data-driven strategies facilitate:

- Real-time monitoring

- Predictive maintenance

- Actionable insights

This ultimately leads to improved decision-making and operational performance. How can your organization leverage these strategies to achieve similar results? The implications of adopting such technologies are profound, potentially transforming operational workflows and driving competitive advantage.

Introduction

In an industry where precision and efficiency dictate success, the integration of manufacturing data analytics is transforming the landscape. By harnessing the power of data, manufacturers can unlock insights that streamline operations, enhance product quality, and reduce costs. These features of data analytics not only provide a competitive edge but also foster innovation and adaptability in a rapidly changing market. However, the challenge lies in effectively utilizing these analytics to navigate the complexities of modern manufacturing.

How can organizations leverage data-driven strategies to not only survive but thrive in an increasingly competitive market?

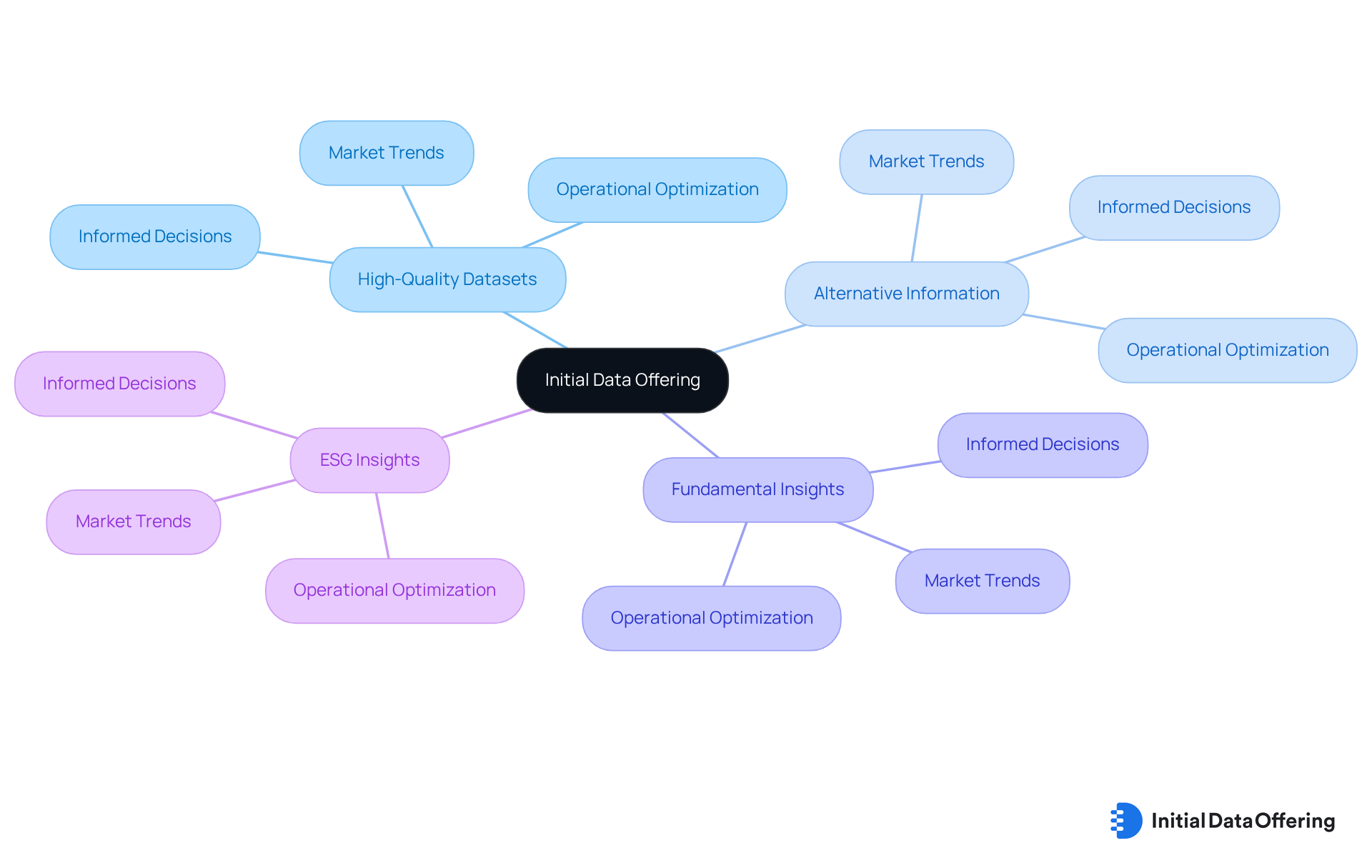

Initial Data Offering: Access High-Quality Datasets for Informed Manufacturing Decisions

The Initial Data Offering (IDO) acts as a centralized hub for high-quality datasets specifically designed for manufacturing data analytics in the manufacturing sector. These datasets feature alternative information, fundamental insights, and ESG insights, providing a comprehensive resource for producers. The advantage of accessing such curated datasets for manufacturing data analytics lies in the ability to make informed decisions based on actionable intelligence. Consequently, this empowers businesses to stay ahead of market trends and effectively optimize their operations.

How can your organization leverage these insights to enhance decision-making and drive performance?

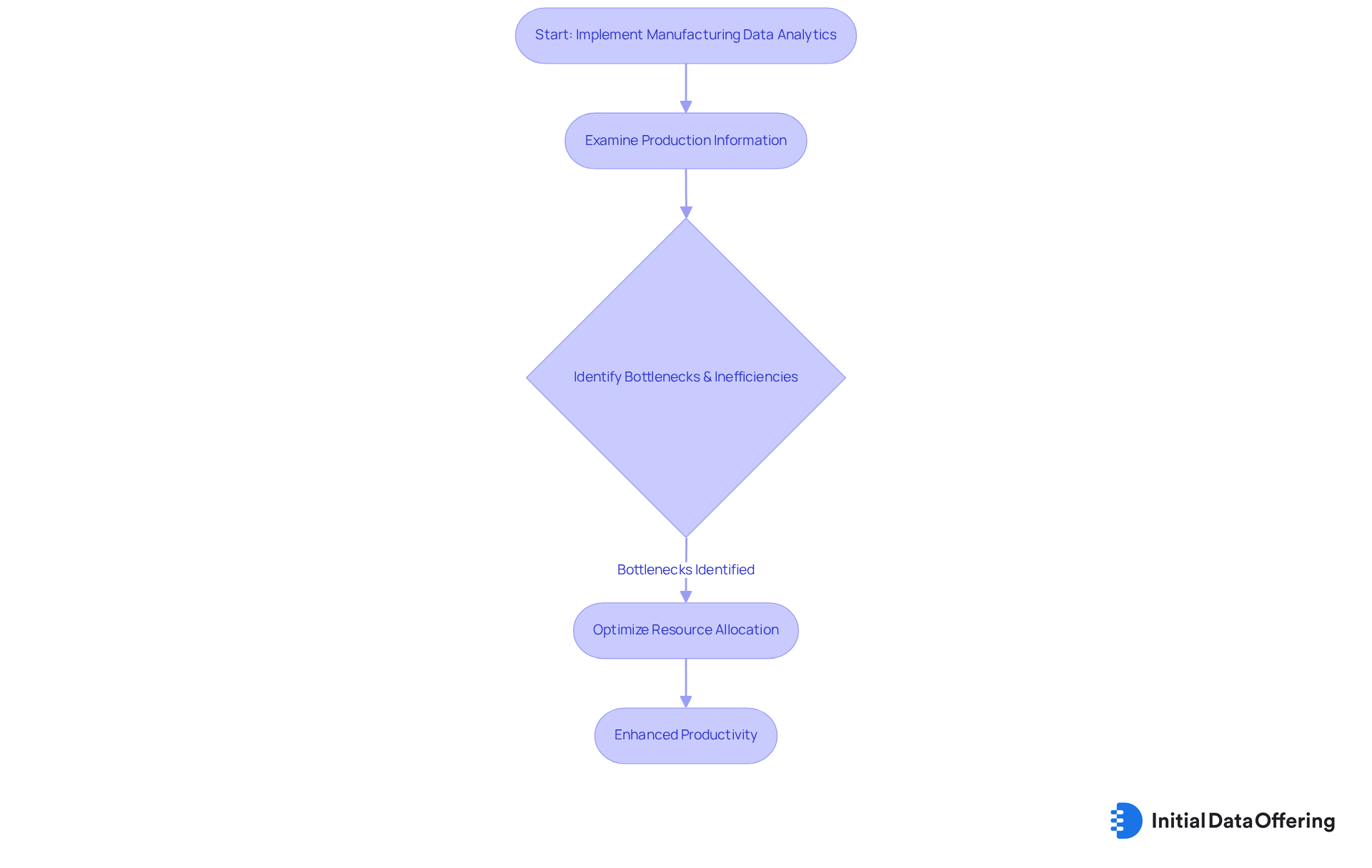

Operational Efficiency: Streamline Processes with Manufacturing Data Analytics

Manufacturing data analytics serves as a crucial feature in streamlining processes. By examining production information, producers can identify bottlenecks and inefficiencies within their workflows. The advantage of implementing data-driven strategies lies in the optimization of resource allocation, which leads to reduced waste and enhanced productivity.

For instance, real-time data monitoring provides the benefit of dynamically adjusting production schedules, ensuring effective utilization of resources.

How might these insights apply to your operations? By leveraging manufacturing data analytics, manufacturers can transform their processes, creating a more efficient and productive environment.

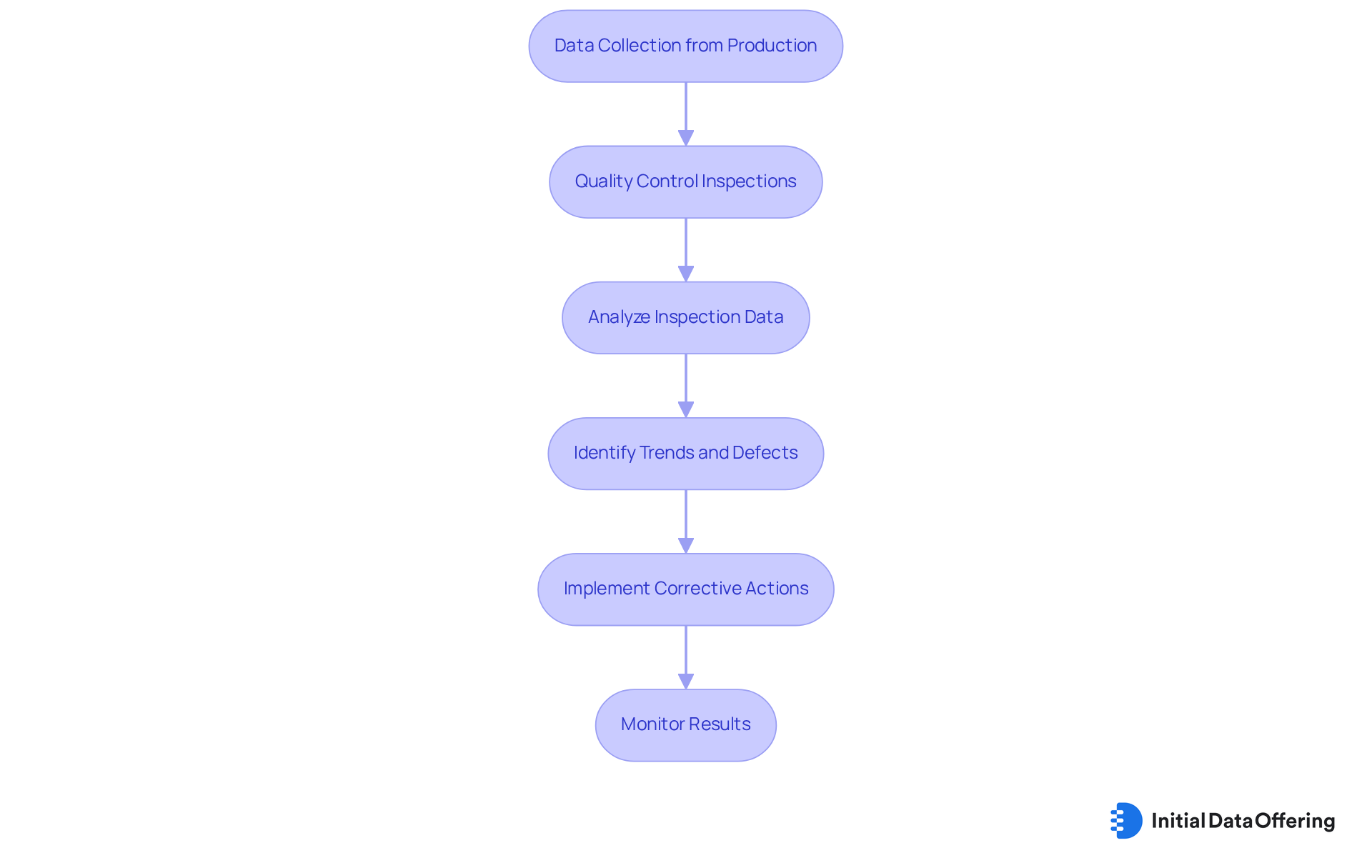

Product Quality Improvement: Leverage Data Analytics to Enhance Manufacturing Standards

Manufacturing data analytics serves as a vital tool for producers aiming to enhance product quality by providing valuable insights into their production processes. Utilizing features such as statistical process control and real-time monitoring, producers can gain significant advantages, including early detection of defects and the ability to implement corrective actions swiftly.

For instance, when examining data from quality control inspections, producers can uncover trends that lead to flaws. This proactive approach allows them to modify processes in advance, thereby upholding high-quality benchmarks.

How might these insights influence your production strategies? By leveraging manufacturing data analytics, producers not only improve their operational efficiency but also ensure that they consistently meet quality standards.

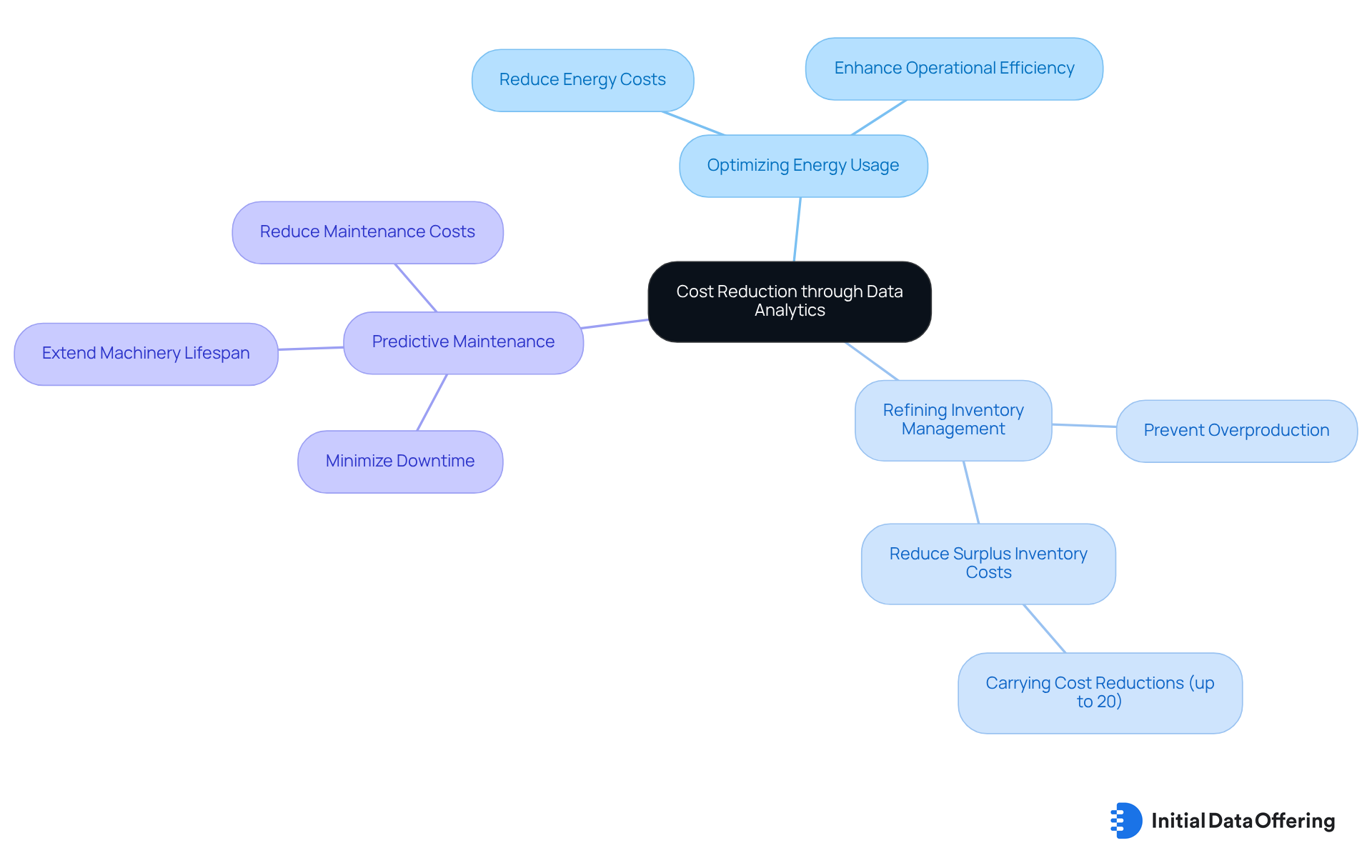

Cost Reduction: Utilize Data Analytics to Minimize Manufacturing Expenses

Manufacturing data analytics serves as a vital feature in driving cost reductions within the manufacturing sector. By leveraging operational information, manufacturers can pinpoint specific areas for cost reduction, including:

- Optimizing energy usage

- Refining inventory management practices

The advantage of predictive analysis lies in its ability to facilitate more accurate demand forecasting, which not only helps prevent overproduction but also reduces expenses related to surplus inventory. Companies that implement data-driven inventory management strategies often benefit from carrying cost reductions of up to 20%.

Furthermore, the benefit of adopting predictive maintenance techniques can lead to significant savings by extending the lifespan of machinery and minimizing downtime. As the manufacturing landscape evolves, embracing manufacturing data analytics not only enhances efficiency but also promotes a culture of continuous improvement and sustainability.

How might these strategies apply to your operations?

Predictive Maintenance: Prevent Downtime with Advanced Data Analytics Techniques

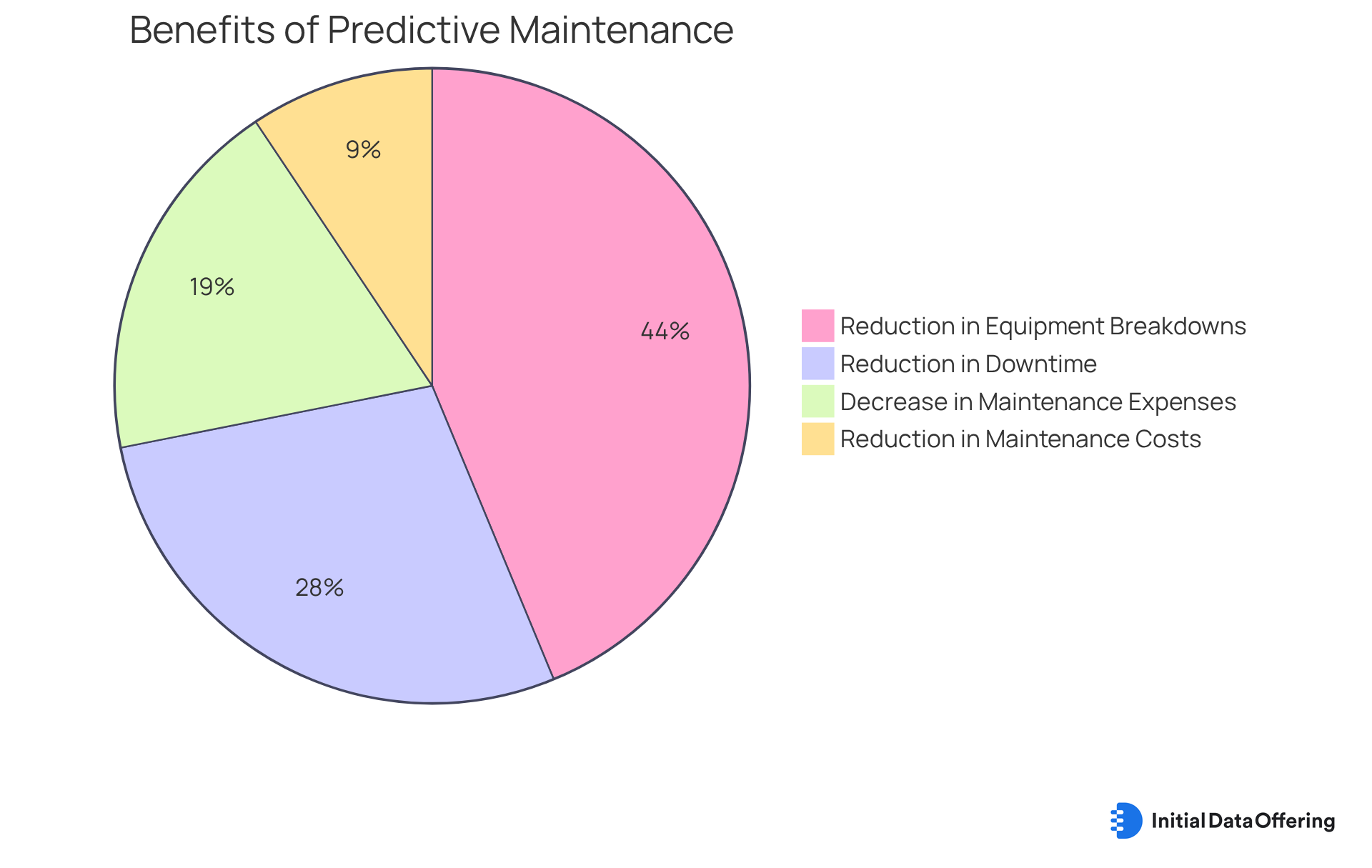

Predictive maintenance employs advanced analytical techniques to foresee equipment failures before they occur. By examining historical data alongside real-time sensor information, producers can discern patterns that signal potential issues. This proactive strategy not only minimizes unplanned downtime but also facilitates timely maintenance and repairs. For example, a global automotive manufacturer achieved a remarkable 45% reduction in downtime through an AI-powered system, resulting in substantial savings of $15 million and a 12% enhancement in overall equipment effectiveness (OEE).

Companies that implement predictive maintenance strategies have reported maintenance cost reductions ranging from 10% to 20%. Furthermore, manufacturers utilizing these techniques have experienced unplanned downtime reductions of up to 50%. Additionally, predictive maintenance can contribute to a 30% decrease in maintenance expenses and an impressive 70% reduction in equipment breakdowns, as highlighted by Predco AI. This underscores its vital role in modern production activities, not only by boosting operational efficiency but also by improving worker safety through the prevention of potentially hazardous equipment failures.

The predictive maintenance market is anticipated to expand from $5.5 billion in 2023 to over $18.5 billion by 2028, emphasizing its growing significance in the industry. How can your organization leverage predictive maintenance to enhance efficiency and safety? The evidence is clear: adopting these strategies can lead to substantial operational benefits.

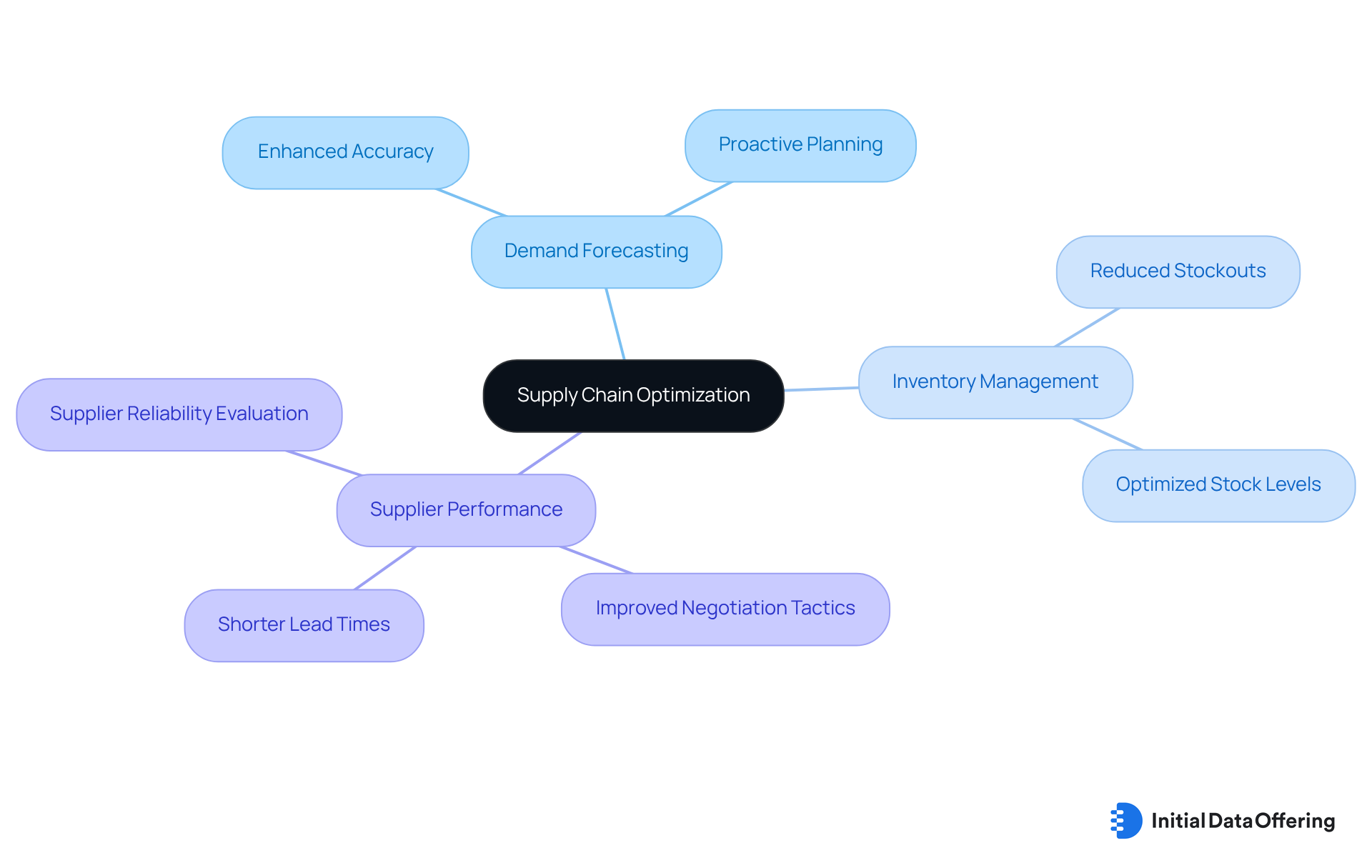

Supply Chain Optimization: Enhance Management with Data-Driven Insights

Manufacturing data analytics play a crucial role in providing data-driven insights that optimize supply chain management within the manufacturing sector. By leveraging manufacturing data analytics to analyze information from diverse sources, manufacturers can significantly enhance their:

- Demand forecasting

- Inventory management

- Supplier performance

For instance, evaluating supplier reliability through data analysis not only leads to improved negotiation tactics but also results in shorter lead times. Companies that adopt manufacturing data analytics for their supply chain strategies typically experience enhanced efficiency and reduced operational costs.

How can your organization leverage these insights to improve its supply chain processes? Embracing manufacturing data analytics can transform your operational capabilities and lead to substantial cost savings.

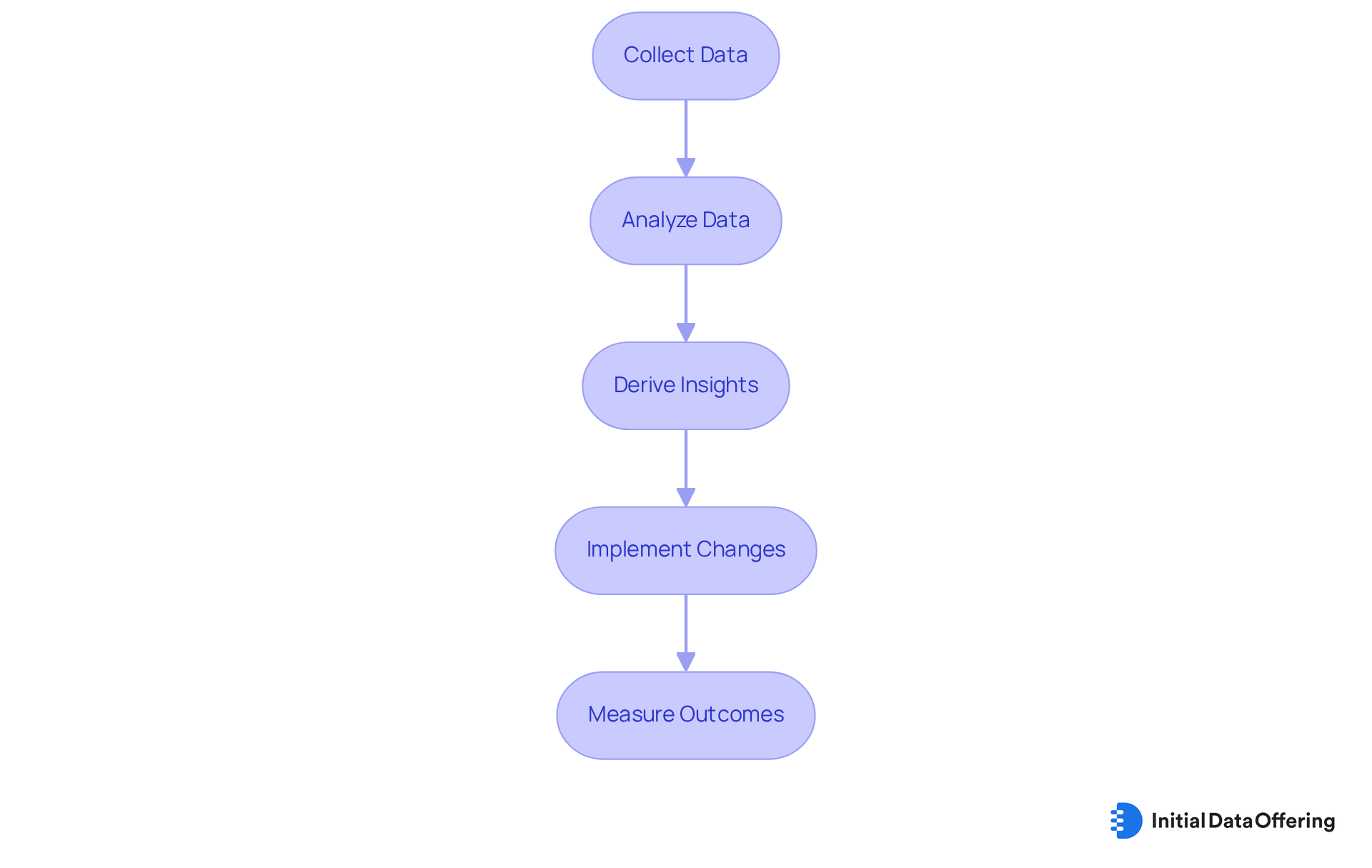

Actionable Insights: Transform Data into Strategic Manufacturing Decisions

Transforming unrefined information into actionable insights using manufacturing data analytics is crucial for strategic decision-making in manufacturing. By employing sophisticated manufacturing data analytics methods, producers can derive significant insights from their information, enabling them to make informed choices. For instance, analyzing customer feedback allows manufacturers to pinpoint areas for product improvement, ultimately enhancing customer satisfaction and loyalty. Companies that adeptly leverage these insights often secure a competitive advantage in the market.

Additionally, strategic decision-making influenced by information analysis allows organizations to enhance operations, lower expenses, and match product offerings with market needs. As the production environment changes, the importance of sophisticated manufacturing data analytics methods becomes more evident, underscoring their contribution to encouraging innovation and propelling business achievement. However, challenges such as integrating information from various sources and ensuring security must be addressed to fully realize the benefits of these analytics.

Performance dashboards can also play a vital role in measuring customer satisfaction and identifying areas for improvement, further enhancing the decision-making process. How can your organization utilize these insights to drive success? By embracing these analytical techniques, manufacturers can not only improve their products but also foster lasting customer relationships.

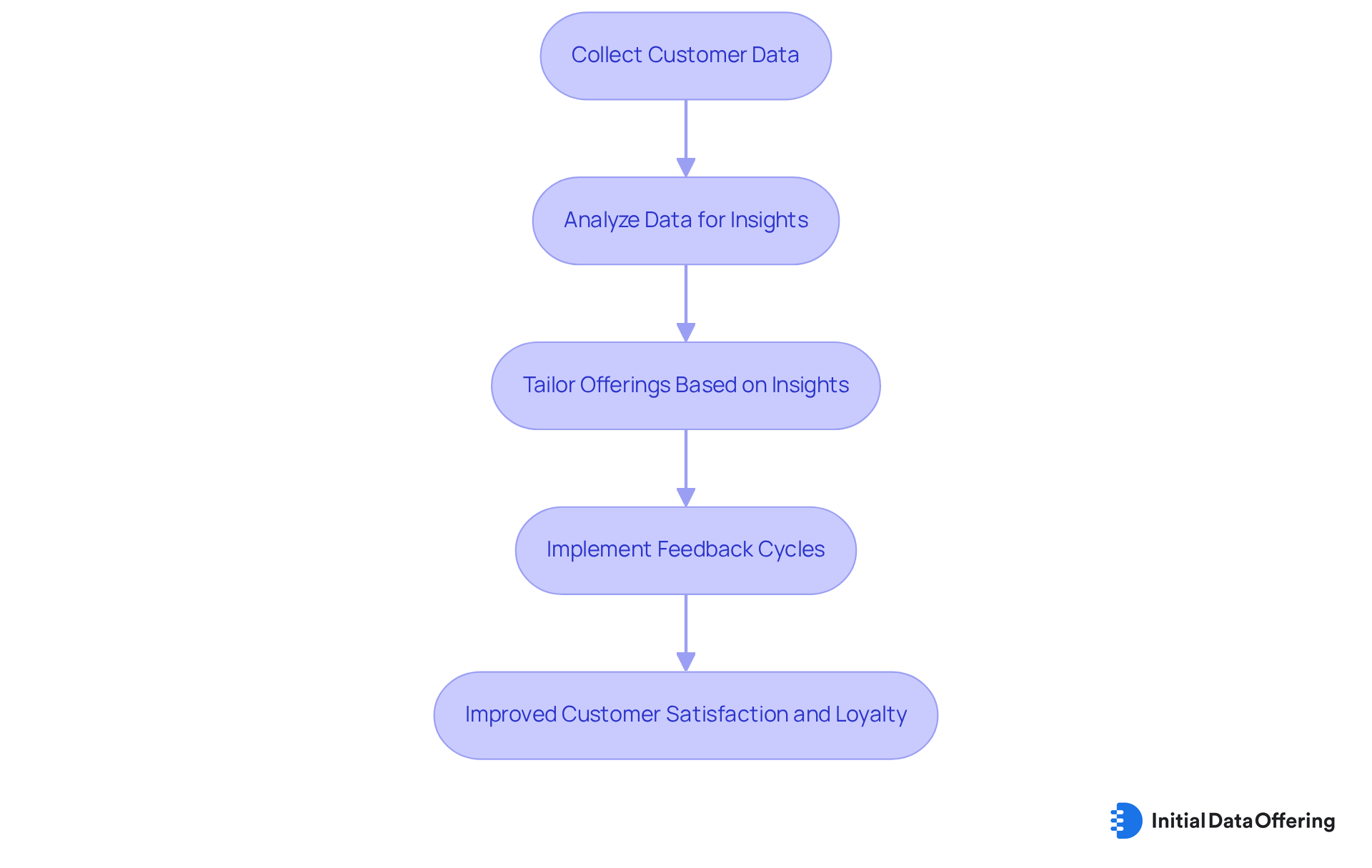

Customer Satisfaction: Improve Experiences with Data-Driven Manufacturing Strategies

Manufacturing data analytics serve as a powerful tool to enhance customer satisfaction through data-driven strategies. By examining client information, producers can gain insights into customer preferences and challenges. This understanding enables them to tailor their offerings effectively. For instance, implementing feedback cycles through data analysis helps producers swiftly address client issues, resulting in improved experiences and increased loyalty. Companies that prioritize customer satisfaction through data-driven approaches often experience higher retention rates and a positive brand reputation.

What if your company could leverage data to not only meet but exceed customer expectations? By focusing on manufacturing data analytics, manufacturers can not only identify customer needs but also adapt their products and services accordingly. This proactive approach not only resolves issues more efficiently but also fosters a deeper connection with customers. Ultimately, by embracing these strategies, businesses position themselves for long-term success in a competitive landscape.

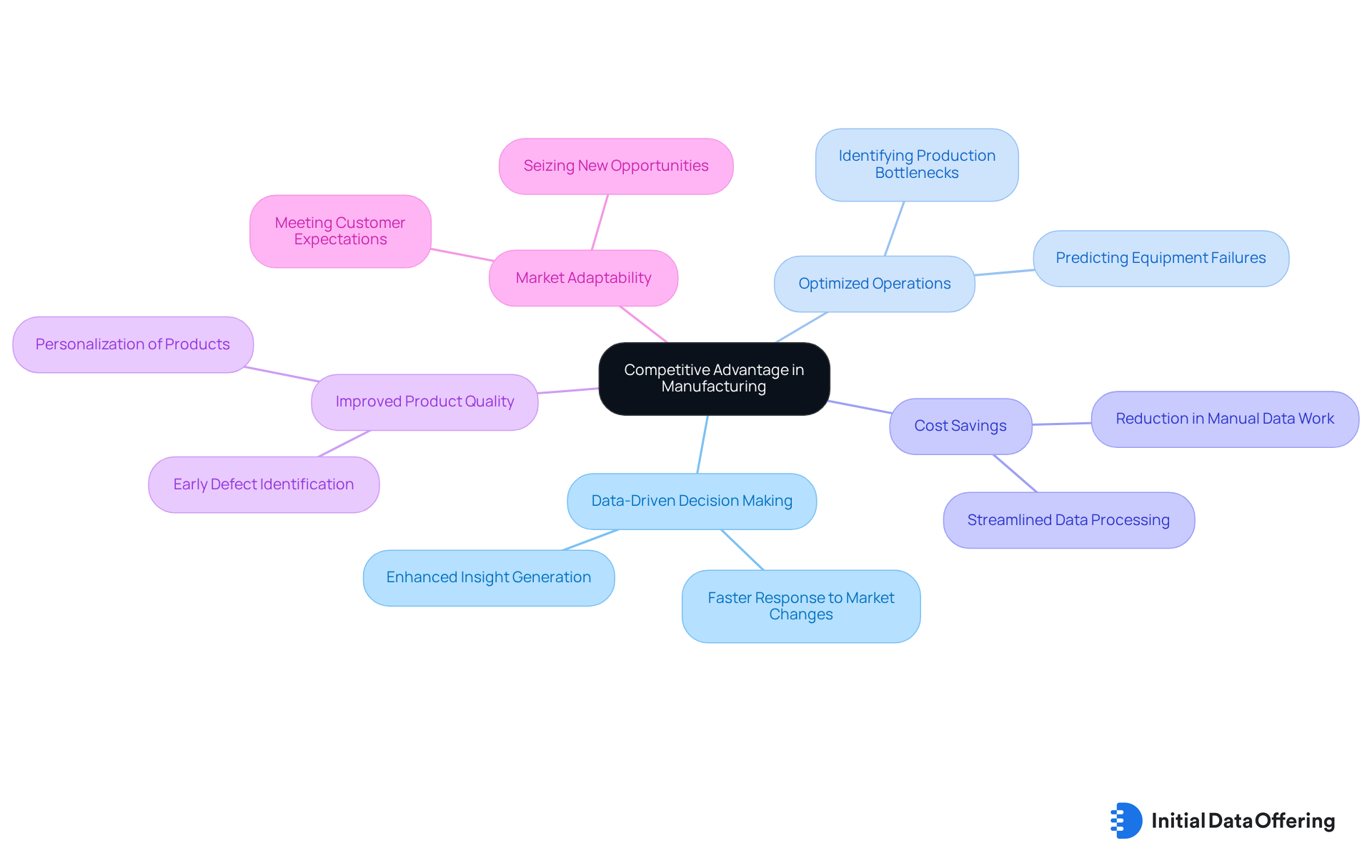

Competitive Advantage: Gain Edge in Manufacturing with Data Analytics

In today's competitive manufacturing environment, the ability to leverage manufacturing data analytics is a significant asset. By leveraging manufacturing data analytics to inform decision-making, producers can optimize their operations, reduce costs, and enhance product quality. This data-driven approach not only positions companies to respond effectively to market changes and customer demands but also leads to increased market share and profitability. For example, firms that engage in sophisticated data analysis often outperform their rivals in key performance indicators.

What does this mean for manufacturers? By adopting data-driven strategies, companies can gain a competitive edge. The advantages are clear: optimized processes, cost savings, and improved product quality. The benefits extend beyond immediate operational improvements; they also enhance a company's ability to adapt to shifting market dynamics. Businesses that harness the power of data are better equipped to meet customer expectations and seize new opportunities.

Ultimately, the integration of manufacturing data analytics into manufacturing practices is not just a trend; it is a crucial step towards sustained success. Companies that prioritize data-driven decision-making are likely to see tangible results in their performance metrics. As the landscape of manufacturing continues to evolve, the question remains: how can your organization leverage data to stay ahead?

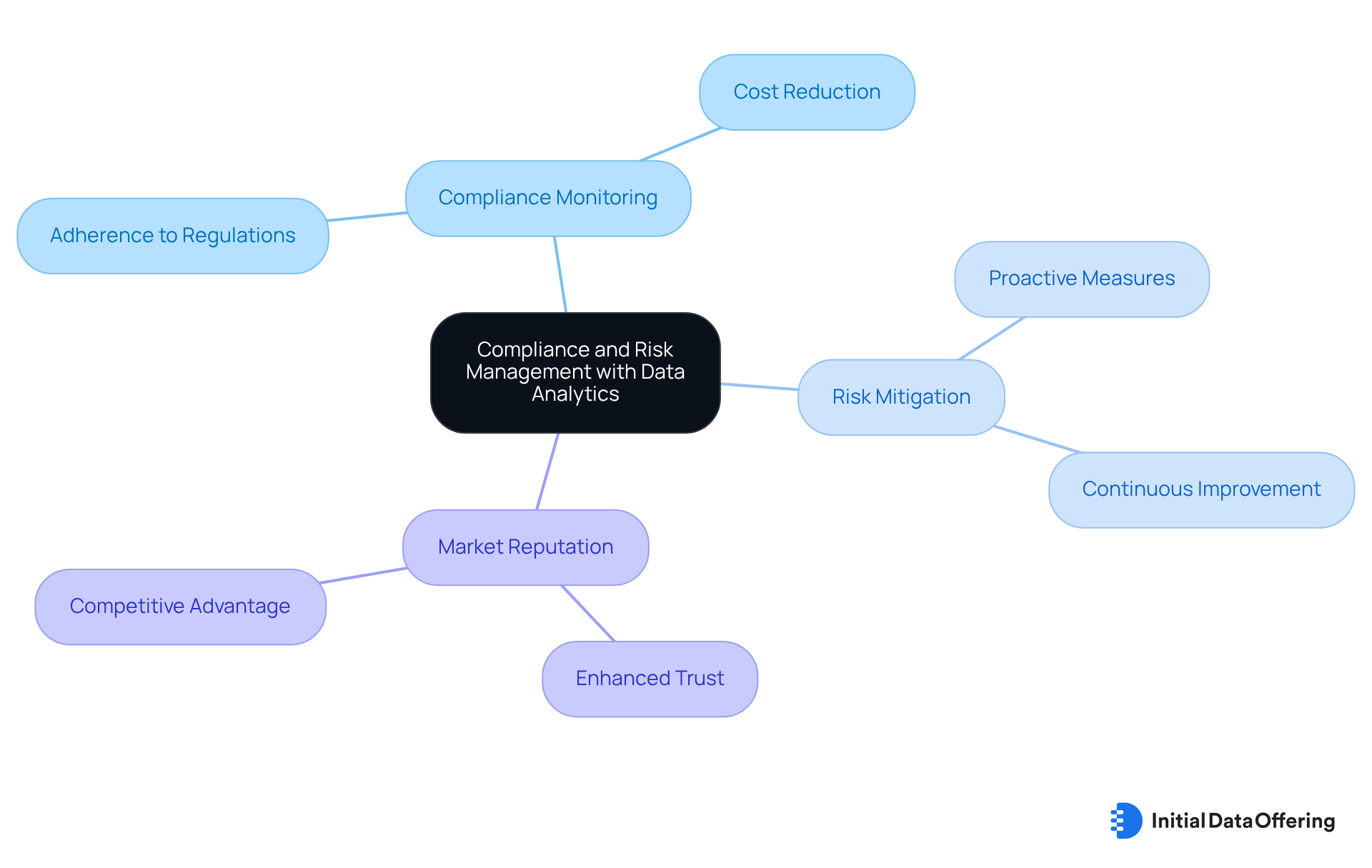

Compliance and Risk Management: Ensure Adherence with Data Analytics Solutions

Data analytics solutions, specifically manufacturing data analytics, serve as essential tools in compliance and risk management within the manufacturing sector. By examining operational information, producers can identify compliance deficiencies and potential hazards, allowing for proactive measures to be taken.

For example, the implementation of manufacturing data analytics in compliance monitoring enables manufacturers to adhere to industry regulations and standards, thereby reducing the likelihood of costly violations. Companies that prioritize compliance through manufacturing data analytics not only mitigate risks but also enhance their market reputation.

How can your organization leverage data analytics to improve compliance and risk management? By adopting these solutions, manufacturers can foster a culture of continuous improvement and ensure long-term sustainability.

Conclusion

Harnessing the power of manufacturing data analytics is essential for organizations aiming to enhance efficiency, improve product quality, and reduce costs. By leveraging high-quality datasets and advanced analytical techniques, manufacturers can make informed decisions that optimize operations and drive competitive advantage. This data-driven approach not only streamlines processes but also fosters a culture of continuous improvement, ensuring that businesses remain agile and responsive to market demands.

Several key benefits of manufacturing data analytics are evident. For instance:

- Operational efficiency is achieved through real-time monitoring.

- Product quality is enhanced via proactive defect detection.

- Significant cost reductions can be realized through predictive maintenance and optimized resource allocation.

The importance of actionable insights for strategic decision-making and customer satisfaction cannot be overstated, illustrating how data analytics can transform manufacturing practices.

As the manufacturing landscape evolves, the integration of data analytics solutions becomes increasingly critical. Organizations that embrace these technologies will not only enhance their operational capabilities but also position themselves for long-term success in a competitive market. The challenge lies in effectively implementing these strategies; however, the potential rewards—improved efficiency, reduced costs, and heightened customer satisfaction—are well worth the effort. Embracing data analytics is not merely a trend; it is a crucial step towards achieving sustained excellence in manufacturing.

Frequently Asked Questions

What is the Initial Data Offering (IDO)?

The Initial Data Offering (IDO) is a centralized hub that provides high-quality datasets specifically designed for manufacturing data analytics. These datasets include alternative information, fundamental insights, and ESG insights, enabling informed decision-making in the manufacturing sector.

How can organizations leverage the insights from the IDO?

Organizations can leverage insights from the IDO to make informed decisions based on actionable intelligence, allowing them to stay ahead of market trends and optimize their operations effectively.

What role does manufacturing data analytics play in operational efficiency?

Manufacturing data analytics plays a crucial role in streamlining processes by identifying bottlenecks and inefficiencies within workflows. This leads to optimized resource allocation, reduced waste, and enhanced productivity.

How does real-time data monitoring benefit manufacturing processes?

Real-time data monitoring allows for dynamically adjusting production schedules, ensuring effective utilization of resources and contributing to a more efficient manufacturing environment.

How can data analytics improve product quality in manufacturing?

Data analytics improves product quality by providing insights into production processes, enabling early detection of defects and swift implementation of corrective actions. This proactive approach helps maintain high-quality benchmarks.

What tools do manufacturers use to enhance product quality through data analytics?

Manufacturers utilize tools such as statistical process control and real-time monitoring to uncover trends in quality control inspections, which helps in modifying processes to avoid flaws.